Lemvig, January 9th, 2017

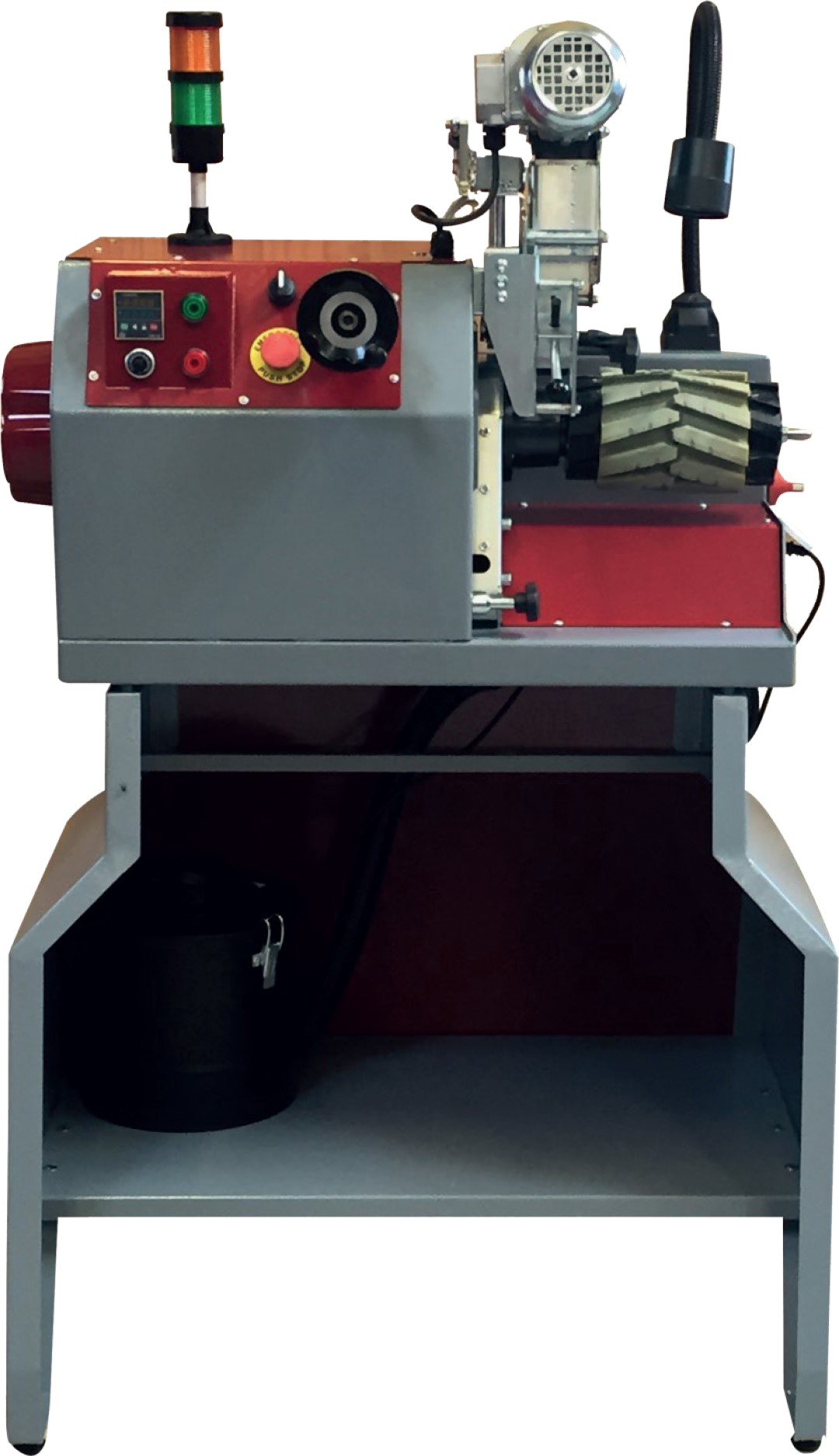

Since the beginning of this pelting season we have had an Edge Master 902 available in our pelting facility.

We planned to use rolls cut on Edge Master 902 on 1 scraping machine and thereby compare the quality of grinding work from Edge Master 902 relative to the impellers we otherwise apply.

During the first 2 days, we discovered that we could reduce the pressure by 20-25% on the rolls which were cut on Edge Master 902. For professionals, there is no doubt that a reduced pressure when scraping also reduces the risk of broken skins.

In addition, it surprised us that the noise level was also reduced, due to a greater uniformity of the teeth of the rolls we sharpened ourselves.

We therefore changed our decision, and chose to use only rolls we sharpened on the Edge Master the rest of this season.

Besides the grinder, we have had an Edge Probe made available and on this we could measure the individual tooth hight, as well as ensure that we had the necessary clearance angle on the cutters.

In economic terms, there has also been a saving, since we have grinded rollers significantly more times than we usually are able to do from suppliers .

The cost saving this season from using Edge Master has been higher than the cost of the machine itself.

I highly recommend the Edge Master 902 and Edge Probe

For further information please contact me as below

Aksel Mortensen

Pelscenter Vestjylland AMBA

Moeskjærvej 2

7620 Lemvig

Denmark

(+45) 23 30 08 25